3D Post Processing

Read the latest news, developments and opinion pieces on 3D Post Processing from mass finishing specialists PDJ Vibro.

3D printing has swept the world with its promise of rapid prototyping and endless design possibilities. In the midst of this transformation, metal 3D printing has emerged as a key player, offering strong, durable parts suitable for an array of industries.

In the ever-changing industrial technology landscape, we must be wary of the "Emperor's New Clothes" phenomenon. This term, derived from a classic Hans Christian Andersen tale, refers to situations where people are led to believe that something is more than it really is, often due to social pressure or misleading claims.

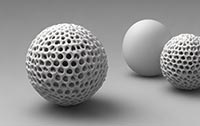

As the field of 3D printing continues to evolve, so too do the methods for finishing these carefully crafted components. Two of the most commonly used processes are blasting and vibratory finishing. Both are highly effective for deburring and polishing 3D printed parts, but they come with their own unique set of pros and cons.

In the ever-progressing world of 3D printing, the finish quality is just as significant as the printing process itself. Amidst a host of finishing techniques, vibratory finishing stands out due to its adaptability and broad-based applicability. Nonetheless, it's important to acknowledge that while it excels in various areas, it does encounter certain limitations.

PDJ Vibro systems are ideal for the post-processing of 3D printed parts due to a multitude of reasons, including their cost-effectiveness and labour efficiency:

PDJ Vibro's revolutionary new compound, NF-15 XP, has taken the world of 3D printed metals by storm. Designed to enhance the finishing process, NF-15 XP delivers unparalleled results, boasting brighter and more vibrant finishes than ever before. This cutting-edge finishing compound represents a significant leap forward in metal finishing technology.

Post-processing of SLS (Selective Laser Sintering) 3D printed parts is essential to achieve a better surface finish. Vibratory finishing is a technique that can be employed to enhance the surface quality of SLS printed components. Let's delve into how vibratory finishing can improve the surface finish of SLS 3D printed parts.

Preparation time for painting plastic components cut by one-third

To assist companies that are considering finishing 3D printed parts automatically using vibratory bowls, guidelines have been prepared by Ogle Models and Prototypes, a leading design and model making bureau based in Letchworth, Hertfordshire.

One of the UK’s leading specialists in 3D printing – Central London based, Digits2Widgets – has enhanced its range of surface finishing services with the recent installation of a vibratory finishing machine from PDJ Vibro Ltd. The new machine is dedicated to the high quality polishing of Nylon SLS parts and produces a very smooth, ivory-like finish.